How ASTM D5511 Validates Biodegradable Plastic Claims

The term “biodegradable” has become a powerful label. But with inconsistent definitions and questionable claims in the market, how do manufacturers ensure their plastics truly break down as advertised? The answer lies in standardized testing—specifically, in ASTM D5511, a recognized method for evaluating plastic biodegradation in landfill conditions.

For manufacturers, brand owners, and sustainability managers, understanding this test is essential, not only to maintain consumer trust but also to ensure compliance with global environmental standards.

What Is ASTM D5511?

ASTM D5511 is a testing standard developed by ASTM International, a globally recognized organization that sets technical benchmarks across industries. This specific method, titled “Standard Test Method for Determining Anaerobic Biodegradation of Plastic Materials Under High-Solids Anaerobic-Digestion Conditions,” measures the rate and extent of biodegradation in environments that simulate biologically active landfills.

This test is designed for plastics that will not encounter oxygen once discarded, such as those buried in municipal solid waste landfills, where anaerobic conditions dominate.

Why Standardized Biodegradation Testing Matters

In the absence of regulated definitions, biodegradable plastic claims can vary widely. This inconsistency has led to consumer confusion and greenwashing concerns. Without lab-based testing to back up claims, manufacturers risk making statements that are legally questionable or environmentally misleading.

Standardized tests provide a consistent, scientific way to measure biodegradation, so results can be fairly compared and verified. They are often required by regulatory bodies, eco-labeling programs, and corporate sustainability auditors. For manufacturers, these tests offer a reliable foundation to support claims and demonstrate product performance.

How the ASTM D5511 Test Simulates Landfill Conditions

ASTM D5511 replicates the unique biological environment of landfills:

- Anaerobic conditions (no oxygen)

- High microbial activity from sludge or compost inoculum

- High-solids content, mimicking buried waste

- Controlled temperature and humidity typical of landfill interiors

In the test, plastic samples are placed in sealed fermentation vessels with this microbial inoculum. As microbes digest the biodegradable portion of the plastic, they produce carbonaceous gases—methane (CH₄) and carbon dioxide (CO₂).

These gases are collected and measured over time. The more gas produced, the more biodegradation is occurring.

What Gas Generation Tells Us About Plastic Breakdown

The key output of ASTM D5511 testing is the volume and composition of gas released. Since plastics are made largely of carbon, the amount of carbon converted to CH₄ and CO₂ directly correlates to how much of the plastic has been metabolized by microorganisms.

Here’s what this gas data reveals:

- Rate of biodegradation: How quickly microbes are breaking down the plastic

- Extent of biodegradation: The percentage of material degraded over the test period

- Environmental relevance: How likely the product is to degrade under landfill-like conditions

By measuring the carbon-weight of the gas against the total carbon in the sample, labs calculate a precise biodegradation percentage. This makes the test far more accurate than simple weight-loss or visual disintegration methods.

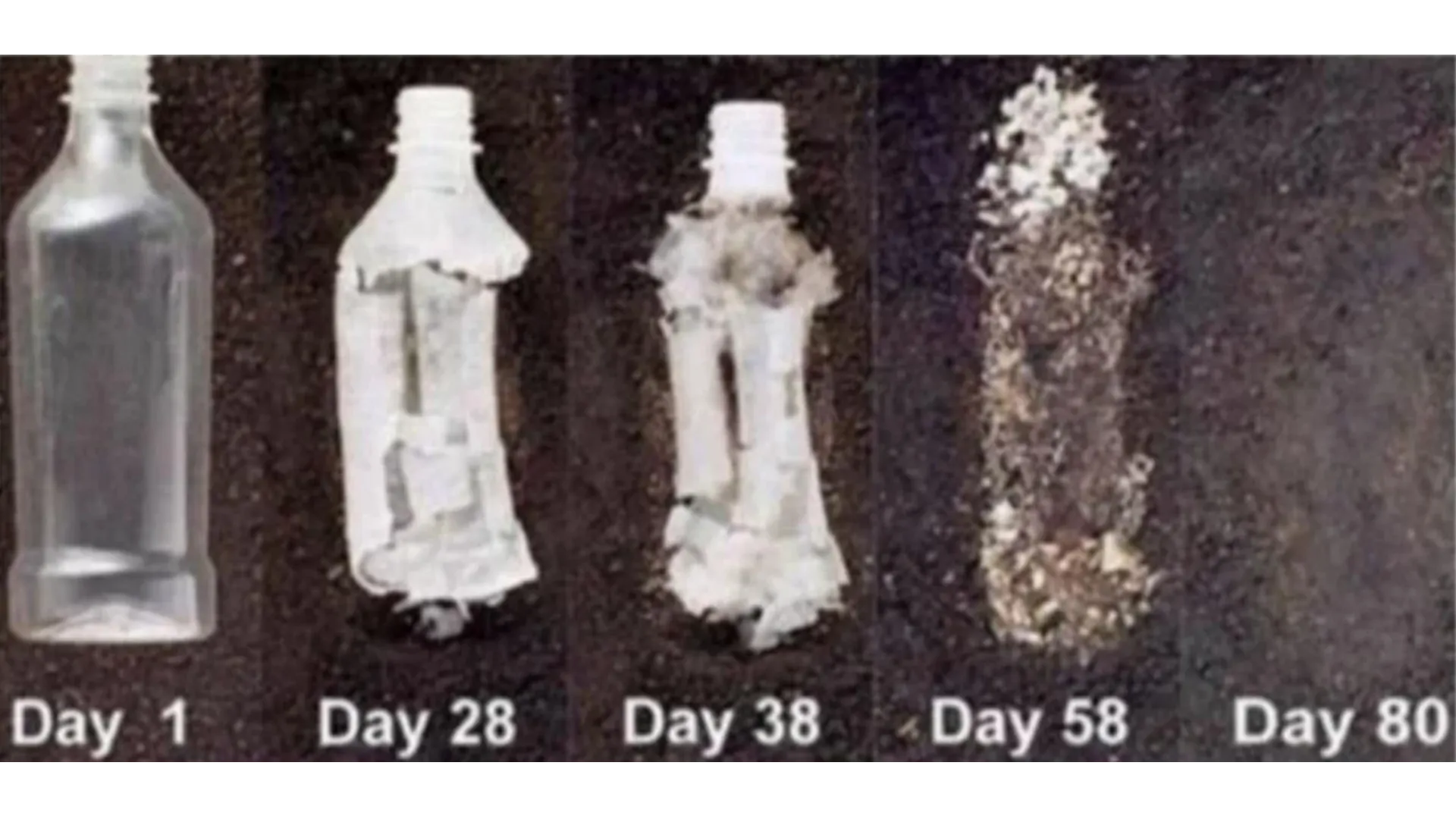

Example: EcoPure® and ASTM D5511 Testing

EcoPure® is an organic additive developed to make conventional plastics biodegradable in landfill conditions. It’s designed to activate microbial breakdown only when placed in anaerobic environments.

Products treated with EcoPure® have been tested under ASTM D5511 protocols with the following results:

- PET bottle sample: 60.1% biodegradation in 1,228 days

- PET-shirt bags: 79.9% biodegradation in 1,779 days

- PS coffee lids: 62% biodegradation over the same period

- Polycarbonate glasses: Over 80% biodegraded in 330 days

These results, generated through third-party labs like Eden Research Laboratory, confirm that EcoPure® enables conventional plastics to break down in landfill-like environments—something untreated plastics typically cannot do.

How Manufacturers Can Use ASTM D5511 to Support Sustainability Claims

Manufacturers incorporating biodegradable additives or developing new resin formulations can use ASTM D5511 to:

- Verify performance: Confirm that treated plastics truly biodegrade in anaerobic settings

- Support marketing and packaging claims: Use credible data to avoid misleading labeling

- Meet regulatory or certification requirements: Provide documentation for government or NGO sustainability programs

- Differentiate products in a competitive market increasingly focused on transparency

Third-party lab testing and published biodegradation data go a long way in building trust with buyers, regulators, and environmentally conscious consumers.

Test methods like ASTM D5511 are essential tools for separating fact from marketing. They provide the scientific backbone behind claims, helping ensure that plastics marketed as biodegradable actually perform that way, especially in landfill conditions, where most plastics are disposed of.

For manufacturers, investing in this kind of testing isn’t just about compliance; it’s about transparency, trust, and creating materials that reflect a commitment to environmental responsibility.